Where metal is concerned though, nothing matters more than accuracy and quality. Two items that are extremely essential to this process are edge rounding tools suppliers, as well as abrasive cleaning brushes. Choosing the appropriate providers for these tools may make a big difference in the quality of your job, whether you’re a manufacturer, engineer, or metalworker. In this post, we’ll talk about why edge rounding tools and abrasive cleaning brushes are important. This will help you figure out how to choose the finest providers for this important metalworking equipment.

What are Edge Rounding Tools, and Why Are They Important?

Edge rounding tools are special tools that are used to smooth down rough edges on metal objects. These instruments are necessary to make sure that the end product is safe to touch and looks good. In businesses where sharp edges might be dangerous or make assembly harder, it’s very important to have good edge rounding equipment. Edge rounding is the process of getting rid of burrs, sharp edges, and other flaws to give the metal item a smooth, rounded surface.

How to Pick the Best Suppliers of Edge Rounding Tools

Choosing the correct edge rounding tool providers may have a big effect on how you operate. You need to choose providers that sell tools that are strong lon, long-lasting, and can handle heavy use. Good vendors usually have a variety of tools that work with different sorts and thicknesses of metal. Also, while choosing a provider, you should think about how reliable they are, how quickly they deliver, and how well they help customers. Choosing the correct partner can help your metalworking business function smoothly and effectively with no extra delays.

Learn about abrasive cleaning brushes for metal.

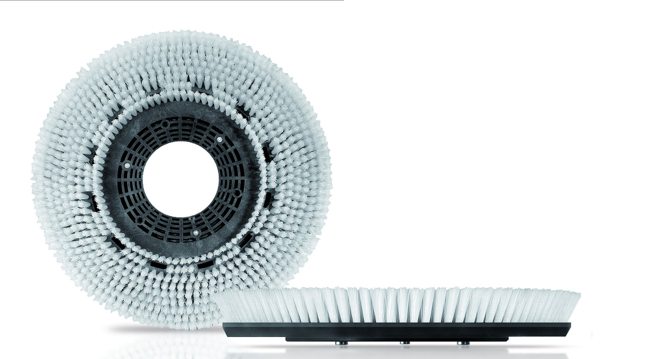

Abrasive cleaning brushes are very important tools in metalworking that are used to clean, deburr, and prepare surfaces. These brushes are made to clean metal surfaces by getting rid of dirt, corrosion, and oxidation. This leaves them clean and ready for further work. Abrasive cleaning brushes are made of different materials, such as steel, brass, or nylon, depending on the metal and the polish you want. They help make surfaces smoother, which is important for items that need to be painted, coated, or welded.

Choosing the Right Abrasive Cleaning Brush for Your Needs

When looking for an abrasive cleaning brush for metal, you need to choose the correct material and bristle strength for the job. For rougher applications that need a lot of cleaning, steel bristles are best. For more sensitive surfaces, softer bristles like nylon may be preferable. When looking for brushes that will last and work well over time, seek for ones that are high-efficiency. You may discover the right brush for your project from reliable vendors who sell a wide range of sizes and varieties.

Why it matters to use high-quality edge rounding tools and abrasive brushes

Edge rounding tools and abrasive cleaning brushes are both designed to last under rigorous use. That’s why it’s important to choose instruments that are of good quality. If you use low-quality tools, they cannot work properly, which might lead to poor outcomes and more downtime. If you get high-quality tools from reliable vendors, you can be confident that your work will be done more quickly and that your completed goods will satisfy industry requirements.

The Advantages of Collaborating with Dependable Suppliers

There are several benefits to working with reliable manufacturers of edge-rounding equipment and abrasive cleaning brushes. First, you can count on getting tools that fit your needs on a regular basis. Second, trustworthy vendors will frequently give you professional advice on how to choose and care for your tools, which will help you get the most out of your purchase. Lastly, if you choose reliable suppliers, you are more likely to get your orders on time, which will keep your workflow going smoothly.

Conclusion

When it comes to metalworking, the equipment you use may have a huge impact on how well and quickly you do your job. You can make sure that your projects go off without a hitch by working with reliable manufacturers of edge-rounding equipment and getting high-quality abrasive cleaning brushes for metal. These tools are necessary for getting the greatest results, whether you’re cleaning metal surfaces or getting rid of sharp edges. If you want to learn more about how to identify trustworthy suppliers and good tools, go to cepicat.com, your go-to place for metalworking solutions.